Cogeneration

Gas Turbine, Gas Engine

Introduction

Gas Turbine and Gas Engine

As the technology leader in Cogeneration or Combined Heat and Power (CHP), Kawasaki Gas Turbine Asia (KGA) provides two types of Cogeneration to produce Electricity and Heat, depending on the power to heat ratio.

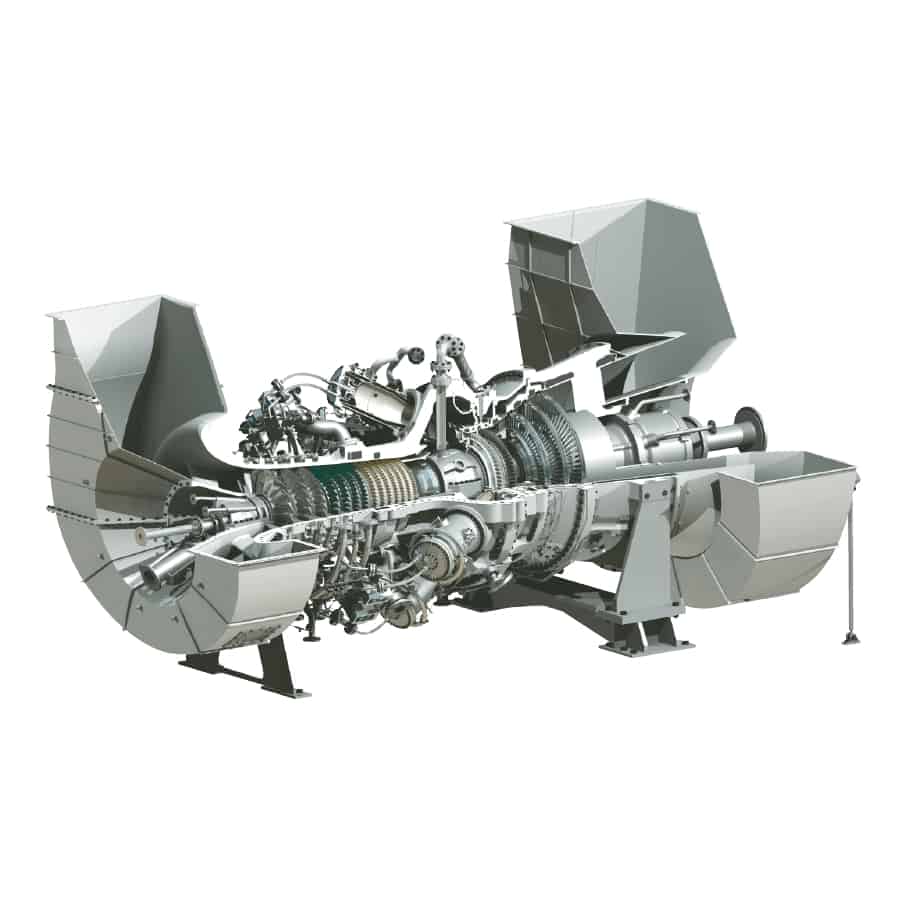

Cogeneration with Gas Turbine Generator

Gas turbine Cogeneration is suitable for industrial users with high heat to power ratio. The combustion of fuel in gas turbine produces the mechanical energy to rotate the alternator / generator, it also churns out large amount of exhaust heat, which is at temperature around 510 deg Celsius.

This large amount of heat can be recovered with a boiler (HRSG) to generate steam, this steam is literally free as it is the byproduct. For example, our GPB80D can provide around 7.6 MW electricity (depending on ambient temperature) and around 17 ton per hour of steam (8 barg saturated steam), please check at below table for the expected power and heat output.

360 view:

| Gas Turbine Model | M1A-13D | M1A-17D | M1T-13D | M5A-01 |

|---|---|---|---|---|

| Gas Turbine Generator Model | GPB15D | GPB17D | GPB30D | GPB50D |

| Electric Output (kW) | 1,450 | 1,755 | 2,850 | 4,450 |

| Heat rate (kJ/kWe-hr) | 15,280 | 13,120 | 15,510 | 11,266 |

| Exhaust gas temperature (℃) | 534 | 526 | 534 | 505 |

| Exhaust Gas Mass Flow (x10³ kg/hr) | 28.5 | 28.8 | 57 | 62.1 |

| HRSG Steam Output (x10³ kg/hr) | 5.1 | 5 | 10.2 | 9.3 |

| Total Thermal Efficiency | 79.7 | 80.4 | 79.3 | 77.2 |

| NOx 02 : 15% (ppm) | 25 | 9*/15 | 25 | 25 |

| Approximate Package Dimension (L, W, H) (m) | 5.3 x 1.65 x 2.35 | 6.0 x 1.85 x 2.55 | 6.0 x 2.4 x 2.8 | 8.7 x 2.6 x 3.5 |

| Approximate Package Weight (dry) (x10³ kg) | 11 | 11.5 | 22 | 55 |

| Gas Turbine Model | M7A-03D | L20A | L30A |

|---|---|---|---|

| Gas Turbine Generator Model | GPB80D | GPB180D | GPB300D |

| Electric Output (kW) | 7,670 | 17,970 | 32,360 |

| Heat rate (kJ/kWe-hr) | 10,820 | 10,690 | 9,196 |

| Exhaust gas temperature (℃) | 526 | 545 | 509 |

| Exhaust Gas Mass Flow (x10³ kg/hr) | 97.6 | 213 | 324.7 |

| HRSG Steam Output (x10³ kg/hr) | 17 | 39.7 | 50.9 |

| Total Thermal Efficiency | 83.2 | 84 | 80.8 |

| NOx 02 : 15% (ppm) | 9*/15 | 15 | |

| Approximate Package Dimension (L, W, H) (m) | 11.5 x 2.8 x 3.6 | 17.2 x 3.5 x 3.4 | 21.6 x 6.2 x 5.7 |

| Approximate Package Weight (dry) (x10³ kg) | 60 | 131 | 250 |

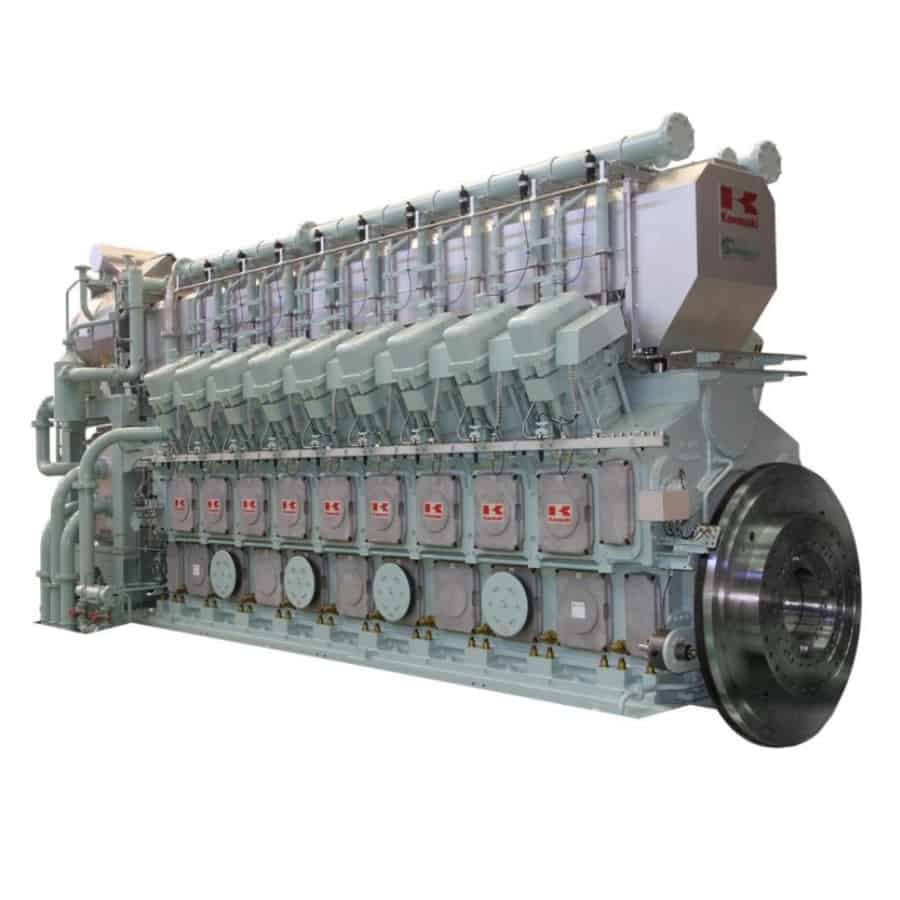

Cogeneration with Medium Speed Gas Engine Generator

Gas Engine Cogeneration is suitable for Industrial users with high power to heat ratio. Gas Engine Generator itself can already generate up to 51% of electrical efficiency, when you have high electrical efficiency, the amount of exhaust heat is lower comparatively, in this case, exhaust temperature is typically around 330 deg Celsius. For example, our KG18 gas engine can provide around 7.8MW electricity and up to 3.6 ton per hour of steam. Furthermore, the heat taken away from the engine cooling jacket can also be recovered to generate hot water at around 90 deg Celsius, this hot water can either be used directly in your heating process or even used in Hot Water Absorption Chiller to generate chilled water for your plant.

Cogeneration Summary Table (Selected Models)

Remarks:

Generator output is based on 15 deg C ambient temperature, and 0 m altitude.

Steam pressure at 8.3 barg saturated with feedwater temperature at 80 deg C.

Natural gas composition is typical.

Detailed GTG / GEG performance for each specific site can be calculated upon request.

Gas Turbine VS Gas Engine

| Specifications/Product | Gas Turbine

|

Gas Engine

|

|---|---|---|

| Energy Ratio of Cogeneration |  |

|

| Electrical Efficiency (LHV) | 29-33% | 48.5-51% |

| Total Efficiency of Cogeneration (LHV) | 77-84% | 63.5-77% |

| Electrical Efficiency (Partial Load) | Good | Very Good |

| Exhaust Heat | High Exhaust Gas Temperature and Amount | Low Exhaust Gas Temperature |

| NOx Emissions (O₂=15%) | 15 – 25ppm (DLE) | 57ppm |

| Vibration | Ultra Low | Low |

| Machine Size | Small | Large |

| Start-up Time | 20 min | 5 min |

| Maintenance Interval | Very Long | Long |

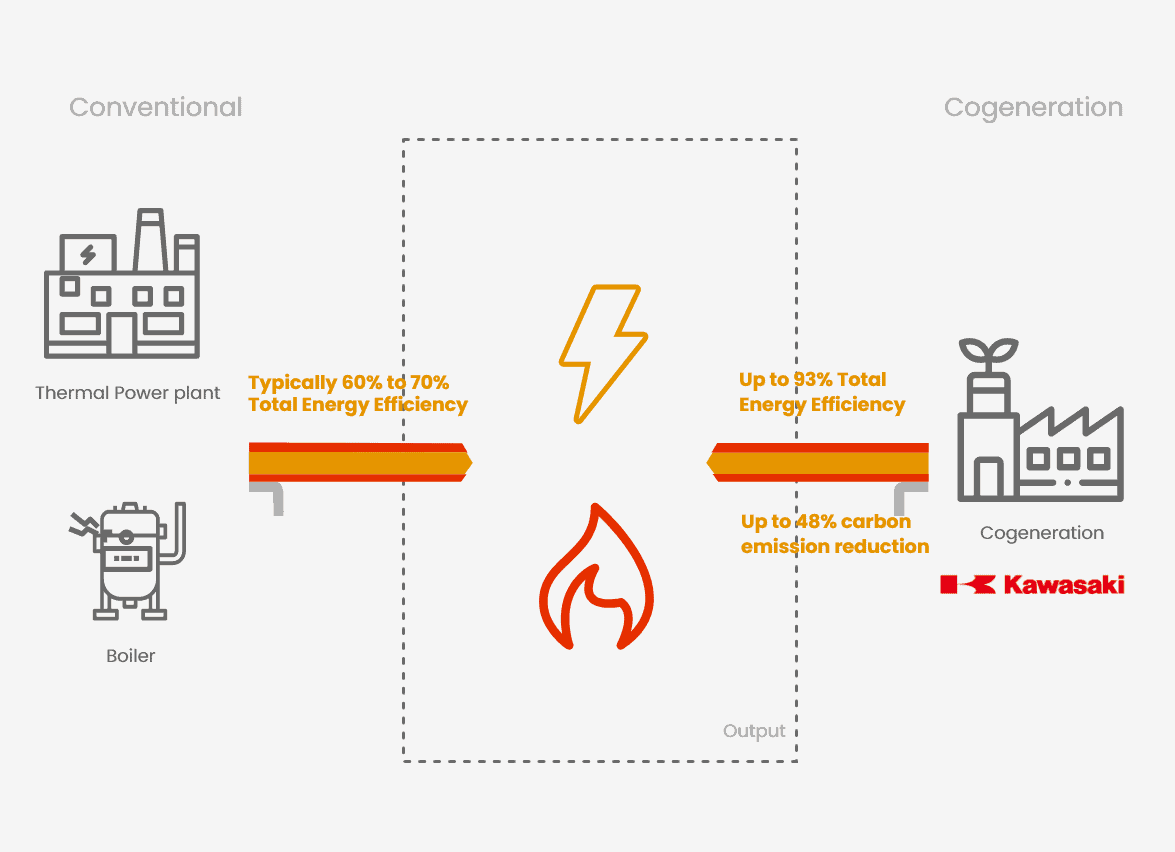

Cogeneration: Cost Effective to Produce Power and Heat.

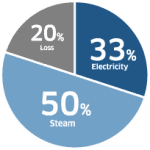

Conventional System

- Lower Capital Expenditure

- Low Energy Efficiency in total

- High Operation Cost (Energy cost, maintenance cost)

- High CO2 emission

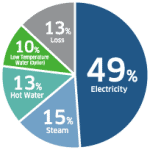

Benefits of Kawasaki Cogeneration System

- Proven Feasible Capital Expenditure

- High Energy Efficiency in total (Up to 93%)

- Lower Operation cost (Energy cost, maintenance cost)

- Very green with low CO2 emission